Quality Control

ISO9001 As Guidelines

Daian factory has passed ISO 9001 certification and applied the principles as our guidelines in our daily manufacturing processes.

Our factory has Disney, Sedex 4P certification and ISO system certification required by domestic market . All of these provided a solid foundation for the cooperation between our company and international famous brands.

From raw material inspection to semi-products inspection, Tumbler/Cup components to finished products testing, we trust the power of standardized process.

Daian 4-Step

Quality Management System

Verifying Qualification of Raw Material Suppliers

Self-Purchased Raw

Materials & Inspection

Standardized

In-Process Quality

Control

Finished Products

Inspection

Sample Tests:

Making Sure Quality of Mass Production

The sample acts as the bridge between quality components and quality mass production. Here in Daian, our unique approach is to test the sample again and again under the most severe condition so that all the vacuum flask body are working to ensure the performance.

Once the sample stand the tests, the QC team is responsible for recording its spec and providing BOM sheet for the mass production procedure.

Electronic Performance Tests:

For Accurate Light Spec

Dimensional Standard Test: To ensure the product's dimensions meet the required precision We strictly test the dimensional standards of samples with precision instruments at every step to ensure the dimensions meet flawless requirements, controlled within a tolerance range of ±0.2mm to ±0.5mm.

Photometric Tests:

For Accurate Light Spec

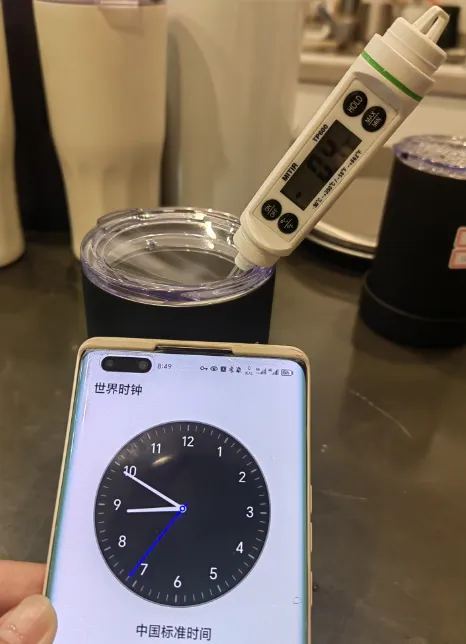

Insulation Test (Heat/Cold Retention): To ensure accurate thermal insulation performance.

To ensure our samples meet your requirements and market standards, we conduct temperature tests in strict accordance with standard procedures and provide a detailed temperature test report.

Extreme Challenge Tests:

For Every Harsh Condition

Spray Coating/Coloring Test: Ensure flawless coloring Conduct finished product tests after the fully automatic spray coating production line to ensure each vacuum tumbler achieves complete and uniform coloring.

Electronic Performance Tests:

For Accurate Light Spec

Finished Product Testing: Ensure the finished products fully meet customer requirements.

Through precise instruments and careful manual inspection, we guarantee the final samples achieve flawless quality, facilitating smoother mass production.

Partner with Us for Market Success

Daian R&D capabilities provide a competitive edge. One-stop services for new/existing brands: from idea to sample, optimization to mass production support.

Let’s create consumer-loved products together. Contact us to start your innovation journey!

KR

KR